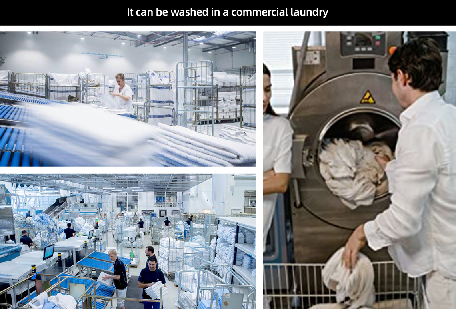

In terms of maintenance, a 28cm fitted sheet is no more challenging than a regular one

When replacing spark plugs, it is important to follow the manufacturer's recommendations for the correct type and gap setting. Using the wrong spark plugs can lead to engine misfires and poor performance. Additionally, it is essential to properly torque the spark plugs to prevent damage to the cylinder head.

If you're looking for quality oil seals, bearings for industry or agriculture, ATV parts, and plenty more, check out The Big Bearing Store. With low prices and same day shipping in most cases, there's no reason to spend time searching the internet when everything you need is all in one place.

In our cutting edge technology centers in the Netherlands, the USA and the UK, we design and develop specific and custom-made rubber sealing parts for many industries.

What is an oil seal and how does it work?

Conventional oil seals

As shown in Figure 1, sealing devices come in two types: contact and non-contact.

Oil seals are among the major contact type sealing devices.

Figure 4: JTEKT oil seal features

ls1 spark plug wires.

Oil Seal Installation Guide

The design and material of a shaft oil seal are crucial factors in determining its effectiveness and durability. High-quality seals are made from durable materials that can withstand high temperatures, pressures, and speeds. They are also designed to maintain a tight seal against the shaft while allowing for smooth rotation without excessive friction or wear.

Oil seals close spaces between fixed and moving parts and protect all kinds of ball and roller bearings. They keep rotating shafts and bearings from pollution and corrosive materials, and also prevent lubricants, oils, and liquids from leakage. An oil seal can have a single lip, double lip and even triple lip, so single lip seal is one lip to seal around the shaft, double lip seal is two lips sealing around this, and triple lip seals have three lips to seal.

Price of Oil Seals: Factors and Considerations

Oil Seal Turbo:

NNK is committed to the best raw materials, and uses advanced technology and equipment to solve oil seal problems for customers. Our products not only ensure the sealing effect, but also minimize the friction force. The service life is longer than the average service life of oil seals. less loss.

MH: O.D. wall is a rubber material

HM: O.D. wall is a metal case

MH(S)H: O.D. wall is metal with a reinforced inner metal case